Plyterra Color

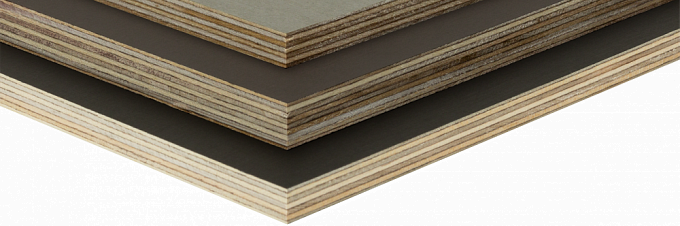

Plyterra Color is a brand for birch plywood overlaid on both sides with a durable melamine film. It is manufactured on the basis of Exterior birch plywood. Multilayer structure of 100% birch plywood guarantees good strength properties of Plyterra Color. WBP glue, used for production of the panels, guarantees excellent bonding properties. Formaldehyde emission level complies with the requirements of E1, EPA TSCA Title VI.

Plywood coated with melamine film is a multi-purpose material which is used in many industries. The density and color of the film can be chosen based on the final use of the panel. First of all, the film faced plywood is widely used to create cutting-edge interior designs. The films that leave the wood grain visible are especially popular as they feature the beautiful authentic texture of wood. Designers provide a variety of simple and sophisticated solutions for wall paneling. At the same time, birch plywood can be used as a structural material for construction of partitions with smooth finish and enhanced surface performance.

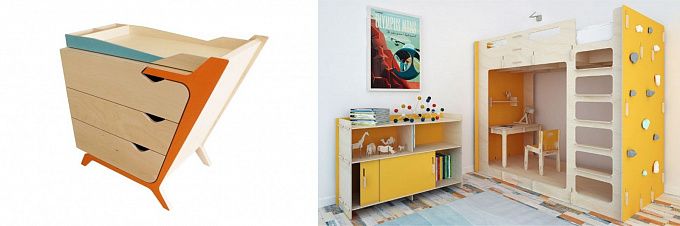

Another popular application of melamine film faced birch plywood among industrial manufacturers, DIY craftsmen and designers is the production of aesthetically pleasing and functional furniture. Storage units, office and kitchen furniture, as well as exhibition stands and booths are only few examples of Plyterra Color practicality.

Plywood overlaid with melamine film is hygienic, free of odor and harmful substances. It makes this environmentally friendly material perfect for production of toys, construction of playgrounds, finishing of interior walls in kindergartens and children’s rooms. It provides wide design opportunities due to a wide range of standard and special colors of melamine film. The material is highly durable and easy-to-clean, which benefits to its long-standing character.

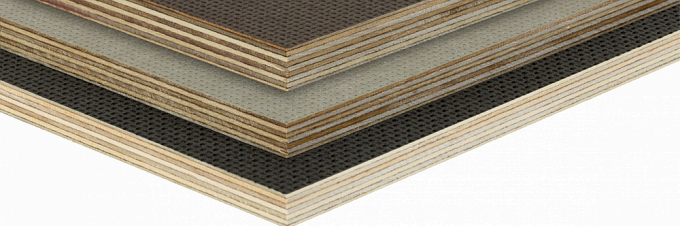

At the same time, film faced plywood withstands various weather conditions. Melamine film retains its bright rich color when exposed to sunlight for continuous period of time and guarantees high visual quality of the laminated plywood. It also ensures better resistance to abrasion and damage. The protective coating prevents the panels from moisture absorption. All this makes this film faced plywood perfect for outdoor use and other demanding applications where wear-resistant surfaces are needed, for example for construction of temporary structures, agricultural and business premises, climbing walls, pedestrian bridges, playgrounds as well as for production of commercial vehicles, advertisement and information boards. Overlaid panels are also available with wire-mesh and hexagonal surfaces.

Smooth durable melamine film makes birch plywood more resistant to impacts and other forms of bruising. The overlaid surface of the panel is resistant to commonly used chemicals, dilute acids and alkalis. Thanks to better resistance to abrasion of the melamine film and stiffness of birch plywood, this product is very popular for concrete formworks.

This laminated plywood from Russian manufacturer is easy to machine and cut to size. A range of sizes and thicknesses is available.

Technical sheet

Specifications

| Thicknesses, mm: | 6,5; 9; 12; 15; 18; 19; 21; 24; 27; 30; 35; 40 |

| Sizes, mm: | 2440x1220 or 1220x2440, 2500x1250 or 1250x2500, 2500x1525, 1525x3050, cut-to-size |

| Grades: | I/I |

| Types of surface: | F/F (smooth/smooth); F/W (smooth/wire-mesh); F/H (smooth/hexa) |

| Film density: | On request |

| The formaldehyde emission according to WKI reports:(limit value: 3,5 mg/h х m2): | 0,1-0,3 mg/h х m2 |

Strength characteristics

| Thickness of plywood, mm | Bending strength, MPa, mean value | Modulus of Elasticity, MPa, mean value | ||

| perpendicular to the fiber | parallel to the fiber | perpendicular to the fiber | parallel to the fiber | |

| 6,5 | 60 | 85 | 4300 | 9500 |

| 9 | 65 | 85 | 5700 | 9000 |

| 12 | 60 | 80 | 6000 | 8500 |

| 15 | 60 | 80 | 6500 | 8500 |

| 18 | 75 | 70 | 7000 | 8500 |

| 19 | 70 | 70 | 7200 | 8000 |

| 21; 24; 27; 30 | 70 | 70 | 7000 | 8000 |

Applications

Contact us

If you are interested in buying Plyterra products, or you need any

additional

information, please contact our sales team.