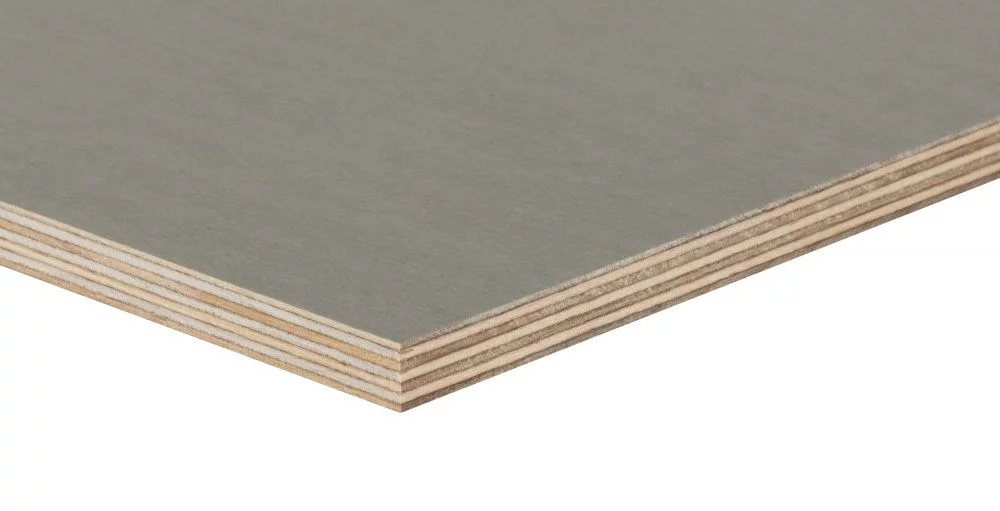

Plyterra Deck Grey

Film faced plywood Plyterra Deck Grey is manufactured on the basis of Exterior birch plywood overlaid with film made of high-density paper, impregnated with phenol-formaldehyde resin, the edges are sealed with acrylic paint. Wear resistance according to Taber test is 400-450 rounds.

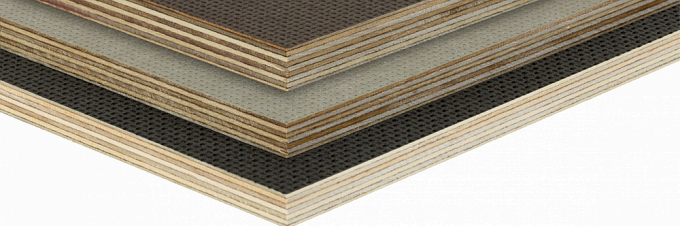

Plyterra Deck Grey has a set of features improved in comparison with standard film faced plywood:

- Twice higher water-resistance indicators

- UV and chemical resistance

- No risk of staining the concrete surface

- Better colour stability

- Twice lower level of formaldehyde emission

The main area of Plyterra Deck Grey application is construction. The surface of the plywood board matches the concrete colour, which makes it perfect for concrete formwork. The surface of the concrete after casting has a more attractive “architectural” appearance.

Technical sheet

Specifications

|

Thicknesses, mm: |

6,5; 9; 12; 15; 18; 19; 21; 24; 27; 30; 35; 40 |

| Sizes, mm: | 22440x1220 or 1220x2440, 2500x1250 or 1250x2500, 2500x1525, 1525x3050, cut-to-size |

| Grades: | I/I |

| Surface type: | F/F (smooth/smooth) |

| Film density: | 120/120, 120/220, 220/220 g/m2 |

| The formaldehyde emission according to WKI reports:(limit value: 3,5 mg/h х m2): |

0,1-0,3 mg/h х m2 |

Surface characteristics

(other film densities are available upon the agreement with a customer)

| Type of surface | Type of surface | Film density, g/m2 | Taber revolutions* | Rolling wear** |

| Plyterra Deck | F/F | 120 | 400-450 rounds | 3500 |

| Plyterra Deck Grey | F/F | 220 | 700-750 rounds | 5000 |

* The films of other densities are availbale on request.

** Abrasion resistance is tested according to DIN 53799/EN 438.

*** Resistance to rolling wear is determined by a method corresponding to SS 923508.

Strength characteristics

| Thickness of plywood, mm | Bending strength, MPa, mean value | Modulus of Elasticity, MPa, mean value | ||

| perpendicular to the fiber | parallel to the fiber | perpendicular to the fiber | parallel to the fiber | |

| 6,5 | 60 | 85 | 4300 | 9500 |

| 9 | 65 | 85 | 5700 | 9000 |

| 12 | 60 | 80 | 6000 | 8500 |

| 15 | 60 | 80 | 6500 | 8500 |

| 18 | 75 | 70 | 7000 | 8500 |

| 19 | 70 | 70 | 7200 | 8000 |

| 21; 24; 27; 30 | 70 | 70 | 7000 | 8000 |

Applications

Contact us

If you are interested in buying Plyterra products, or you need any

additional

information, please contact our sales team.